Spiral Wound Gasket

Spiral wound gaskets have become extremely popular due to the wide variety of available styles and Sizes. Spiral wound gaskets have the ability to recover under the action of fluctuating loads caused by Process fluid pressure and temperature changes, flange face temperature variations, flange rotation, Bolt stress relaxation and creep. Spiral wound gasket are manufactured by alternately winding strips of Metal and soft filler. Spiral wound gaskets can be fabricated of any Metal which is available in thin strip

and which can be welded. It can be manufactured from a range of filler materials according to Different service conditions.

Spiral Wound gaskets are manufactured in dimension From ¼” to 96” and Thickness from 1/8” to 3/8” generally, gaskets thickness Is 0.175” and outer ring Thickness is 0.125” as per ASME 16.20, API605 Std, BS10. These gaskets are made in any non standard Size as per the customer’s specification.

Spiral Wound gaskets are manufactured in dimension From ¼” to 96” and Thickness from 1/8” to 3/8” generally, gaskets thickness is 0.175” and outer ring Thickness is 0.125” as per ASME 16.20, API605 Std, BS10. These gaskets are made in any non standard Size as per the customer’s specification.

Key Benefits :

- High pressure & High Temperature capability

- Wide choice of materials for filler and metal strip

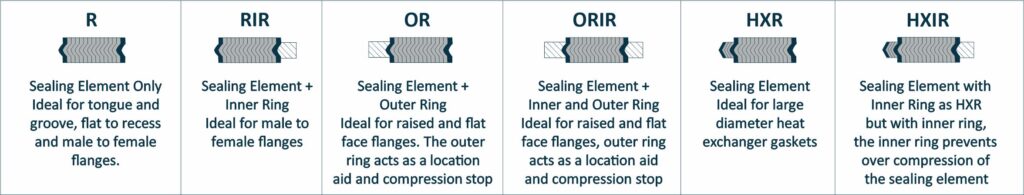

Types of Spiral Wound Gaskets

We recommend a flange surface finish of 3.2 to 6.3ųm Ra (125 – 200 RMS) for operation of the gaskets.

Sealing Element Thickness (Uncompressed)

Spiral wound gaskets are available in the following thicknesses: 4.5 mm and 3.2 mm

Operating Temperatures

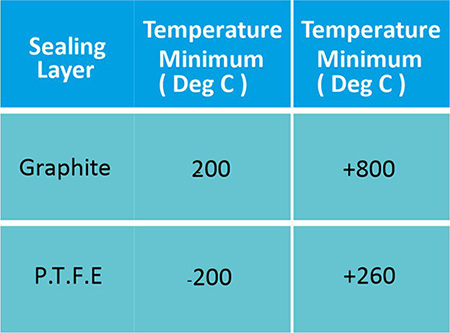

Sealing Material

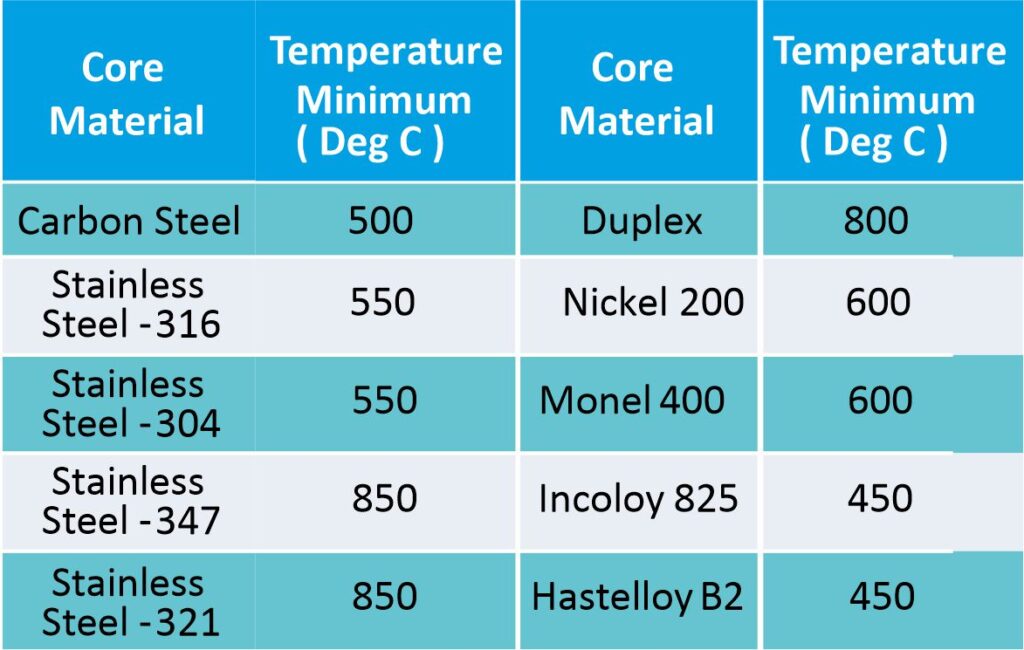

Core Material